PRODUCTS + SERVICE

ALFA LAVAL

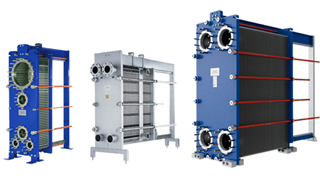

GASKETED PLATE AND FRAME HEAT EXCHANGERS

Gasketed plate and frame heat exchangers provide efficient heat transfer in compact equipment with a small footprint. The units have a flexible design and are easy to service and maintain.

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates is made of gaskets. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger Alfa Laval.

Benefits:

– High energy efficiency

– Flexible configuration

– Easy to install

– High serviceability

The Industrial line is available with various pressing depths and angles of the chevron pattern and various shapes of the corrugation which are all carefully designed and selected to achieve optimal performance. The CurveFlow™ and the chocolate pattern distribution area are two design features available that ensure fluids are evenly distributed across the entire plate. The result is that the entire heat transfer surface is fully utilized and stagnant zones that can result in fouling are avoided.

Are you interested in our products?

Fill out the information request form.